Full Colour Direct Digital Print Direct to product digital printing involves the transfer of ink directly from the print head of a special inkjet machine to the product and can be used to produce full colour printing on flat or slightly curved surfaces. It is difficult to reproduce PMS colour matches and some colours including metallic gold and silver are not possible to achieve. One big advantage of direct digital is that these machines can print a layer of white ink under the copy making them ideal for branding dark coloured products. Screen Printing Screen printing involves forcing ink through a mesh screen with a squeegee onto the product or substrate and is excellent for large print areas on flat or cylindrical objects. Close PMS matches can be achieved on white surfaces but as the colour of the product gets darker the ability to match PMS colours diminishes. Screen printing is best suited for spot colour reproduction and is not recommended for logos with half tones in them. Laser Engraving Laser engraving gives a permanent finish and creates a higher perceived value than direct printing. It is ideal for metal and glass items and because it is a digital process can be used for personalising products with individual names. Different materials produce different effects when engraved and if you are uncertain about the engraved finish please ask for a pre-production sample. Foil Embossing Foil Stamping, (also known as an application) typically a commercial printing process, is the application of metallic or pigmented foil on to a solid surface by application of a heated die onto foil , making it permanently adhere to the surface below leaving the design of the dye.

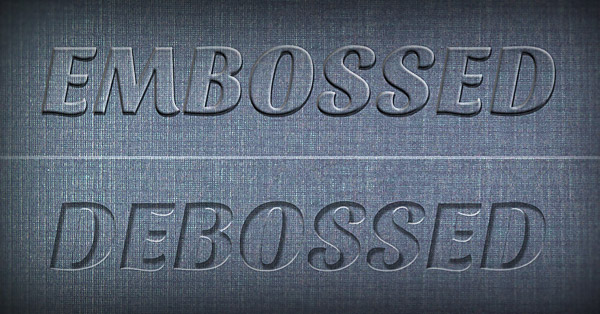

Sublimation Sublimation is achieved by heat transferring a digitally printed full colour image from a paper transfer to the product. This process can reproduce stunning, vivid, full colour graphics but there is limited control over the colour outcomes which makes reproducing PMS colours very difficult and in some cases impossible. Only certain surfaces and materials can be branded with sublimation printing. Pad Printing Pad printing uses a silicone pad to transfer an image to a product from a laser etched printing plate. Pad printing is one of the most practical and popular ways of branding promotional products due to its ability to reproduce images on uneven or curved surfaces Close PMS matches can be achieved on white surfaces but as the colour of the product gets darker the ability to match PMS colour. Embossing/Debossing Blind Emboss, Blind Embossing does not include the use of ink or foil to highlight the embossed area. The change in the dimensional appearance of the material is the only noticeable difference resulting from the embossing. The blind embossing process provides a clean and distinctive or subtle image on paper stock. Embossing with give you a raised finish, where as a deboss will give you an indented image. A debossed image is a more common method used for promotional products.

SupaColour Supacolour is a new way of branding a wide range of products and promotional items. The colour is produced digitally, meaning the images can have millions of colours without the need for expensive setups. Supacolour can produce photo quality art and high detail with none of the limitations of the other digital processes. The transfer is produced using a hybrid of digital for the colours and traditional transfer printing. There is no cutting involved, and there is no product coloured fill needed to help with small lettering and complex images, which is why they are superior to normal digital vinyl transfers. Supacolour simplifies the whole branding process. |